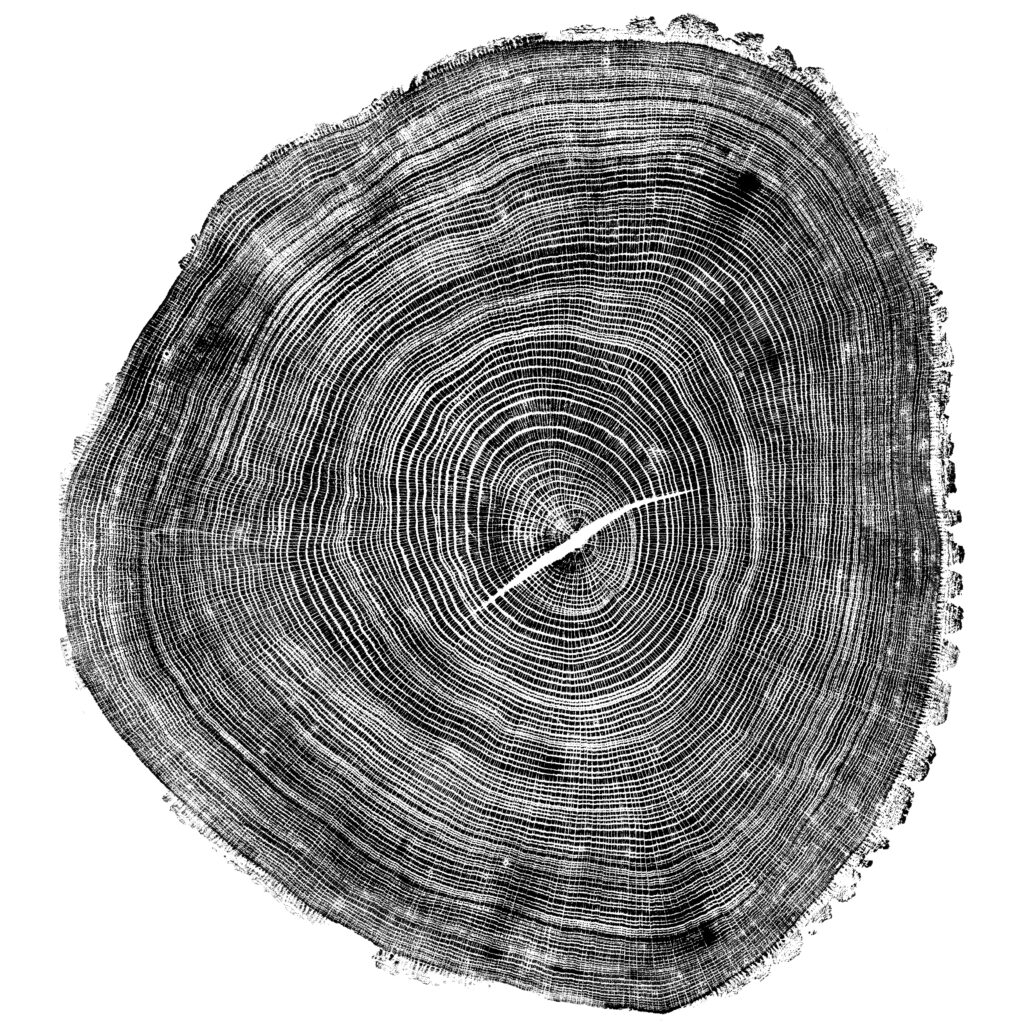

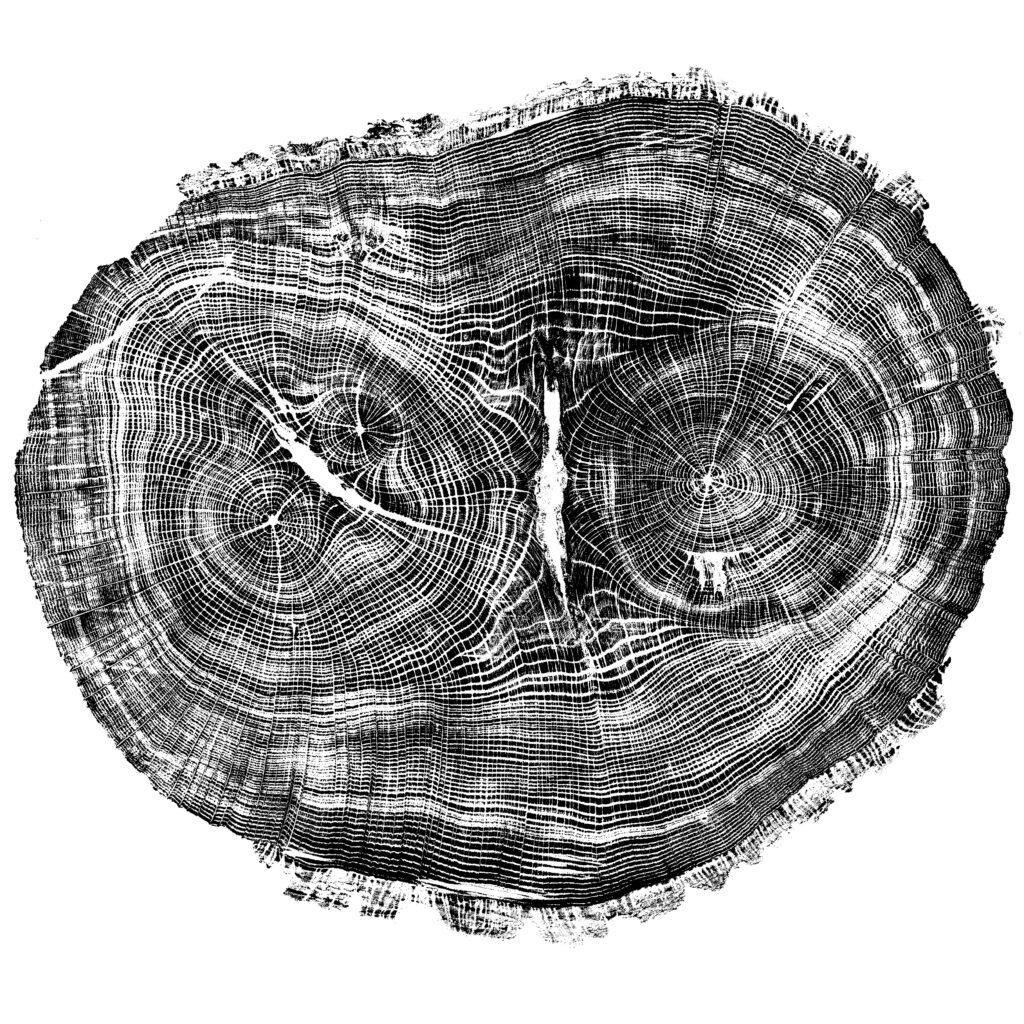

We don’t see a piece of furniture as an inanimate object. But a living thing. With a story and life of its own.

“A culture is no better

than its woods”

Using carefully-considered design and craftsmanship, and sustainable finishes and materials. We bring the natural world into your world.

From the forests of Burgundy to our Vietnamese workshops. To your kitchen, living room or study.

Because we create solid-wood furniture full of life and character. That celebrates nature in all its imperfections, limitless variations, colours, textures and hues.

All its beauty. Into your home. To live with you.

“When we use trees respectfully and economically, we have one of the greatest resources on the earth.”